How to Tell if Your Door Lock Is Pick-Resistant

“Pick-resistant” doesn’t mean unpickable—it means a lock is engineered to make covert entry difficult, slow, noisy, and impractical for most attackers. This guide explains the visible and verifiable signs of pick resistance, how to read certifications and grades, and what to ask a locksmith so you can choose hardware that stands up to real-world attempts without sacrificing everyday usability.

What “Pick-Resistant” Really Means

Lock picking covers a range of covert techniques—manipulating pins, wafers, sliders, discs, or sidebars with specialized tools to mimic the action of the correct key. Pick-resistant locks aren’t magic; they use design features that frustrate manipulation: security pins that lie to the tool, keyways that deny tool movement, tight manufacturing tolerances, secondary locking systems (like sidebars), and hardened parts that resist destructive shortcuts. The result is time, noise, and skill requirements that most opportunists don’t have.

Because attackers choose the easiest route, your goal is to ensure that route is not your lock. Hardware alone isn’t enough—installation quality, door/frame strength, and key control matter just as much. A Grade 1 cylinder in a weak door with loose strikes is still a soft target.

Visible Signals Your Lock Is Built to Resist Picking

These features don’t require lab equipment to spot. They’re clues that your cylinder wasn’t an afterthought and that the manufacturer invested in pick resistance rather than just styling.

Recognized Certifications

Look for listings/marks indicating independent testing for manipulation resistance. Examples include UL 437 (high-security cylinders), BHMA/ANSI A156 grades for auxiliary locks, and regional marks like EN 1303 (Europe) or SKG stars (Netherlands). Certifications signal documented resistance to picking and other covert attacks.

Restricted / Patented Keyways

Keys that can’t be duplicated at kiosks (restricted blanks) indicate a controlled keyway profile. Control over key copies reduces the risk of “practice keys” and bump keys circulating, and usually pairs with tighter tolerances inside the cylinder.

Security Pins & Anti-Manipulation Elements

Modern pin-tumbler cylinders use spool, serrated, or mushroom driver pins that create false feedback for tools. Sliders, sidebars, or rotating elements in dimple and sidebar systems add a second decision layer that raises the difficulty curve.

Tight Tolerances & Solid Feel

Insert a correct key and gently wiggle: quality cylinders exhibit minimal play and a crisp turn. Excess slop and rattling often correlate with loose tolerances that are easier to read and manipulate covertly.

Keyway Geometry

Narrow, paracentric, or curved keyways impede straight-line tool access and limit leverage. If you can see a wide, straight channel through the plug, the lock is friendlier to tools than it should be.

Sidebar / Secondary Locking

Cylinders that combine pins with a sidebar (or use sliders/discs with a sidebar) require multiple elements to align at once, making single-tool manipulation far less reliable.

Hardened Components

While “pick resistance” is the focus, hardened inserts in the face cap and keyway protect against drill-and-probe shortcuts. Attackers often abandon picking when hard parts waste time and tools.

Brand Transparency & Support

Reputable manufacturers publish test standards, grades, and key control policies. If specs are vague (“high security” without details), treat the claim skeptically.

Limits, Misconceptions, and Legal Considerations

No consumer lock is absolutely unpickable. Under lab conditions with specialized tools and unlimited time, many mechanisms yield. The goal is practical security: make picking so slow and uncertain that opportunists move on. Also, possession or use of picking tools may be regulated where you live; always follow your local laws and never test hardware you don’t own or have permission to evaluate.

Time = Your Ally

Pick resistance is measured in minutes under trained attack, not absolutes. The more minutes you buy, the better your odds.

Key Control Matters

Unauthorized copies bypass picking entirely. Restricted keyways and documented key issuance close this loophole.

Door Strength Counts

A great cylinder in a weak door or loose strike is still vulnerable to kicks or prying. Reinforce the frame and strike with 3-inch screws.

Installation Quality

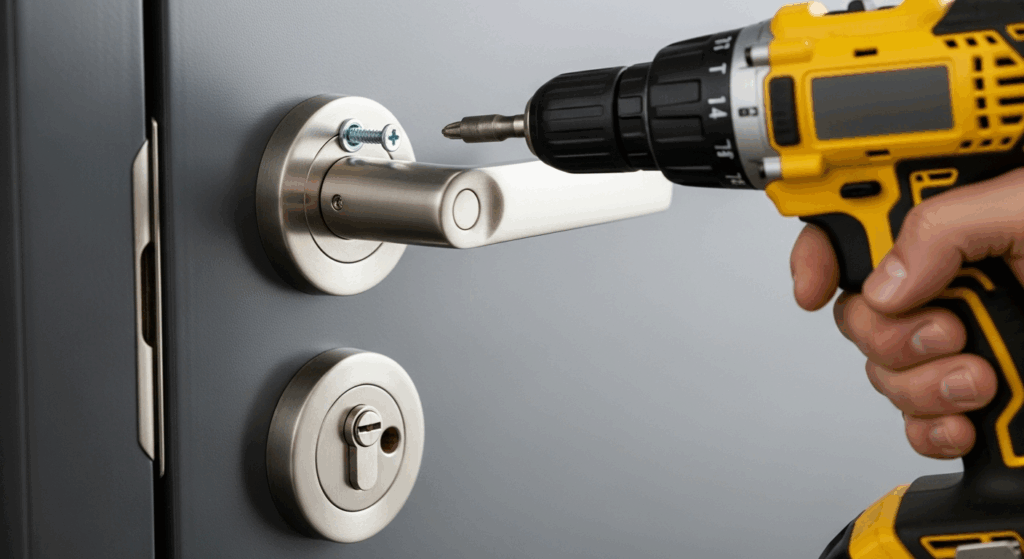

Misaligned latches and sloppy holes defeat tolerances and can create exploitable gaps. Professional installation pays for itself.

How to Assess Your Existing Lock (No Tools, No Disassembly)

These quick checks help you gauge whether your lock likely has meaningful pick resistance. If it fails multiple items, consider an upgrade.

Check for Certifications

Look for markings on the cylinder or packaging indicating UL 437 or a high BHMA/ANSI grade. Take a phone photo of any stamps for later lookup.

Feel for Tolerances

With the correct key inserted, lightly twist back and forth. Crisp engagement and minimal slop are good signs. Spongy feel or excessive rattle suggest looser tolerances.

Examine the Keyway

Curvy or paracentric profiles that block straight access are preferable to wide, straight channels. If you can see straight through the plug, expect lower resistance to manipulation.

Ask About the Key Policy

If your keys were copied at a kiosk with no authorization card, you likely don’t have restricted key control. Consider moving to a system with patent protection and dealer-only duplication.

Research the Cylinder Family

Many deadbolts accept upgrade cores from the same brand (e.g., standard → restricted → high-security). Upgrading the cylinder may retain your hardware aesthetics while boosting resistance.

Practical Upgrade Paths for Pick Resistance

You don’t have to replace the whole lockset to gain better security. Choose the rung that fits your budget and risk level.

Good: Quality Grade 1 Deadbolt + Improved Cylinder

Upgrade to a reputable Grade 1 deadbolt with a cylinder that includes security pins and a paracentric keyway. Add a reinforced strike plate with 3-inch screws into framing.

Better: Restricted Keyway Cylinder

Move to a patented, restricted keyway with dealer-only duplication and security pins. This closes the key-copy loophole while raising pick difficulty.

Best: High-Security Cylinder with Sidebar/Sliders

Choose a cylinder platform that uses pins and a sidebar, or sliders/discs with a sidebar, plus hardened anti-drill inserts and documented pick-resistance testing (e.g., UL 437).

Don’t Forget the Door

Pair any cylinder upgrade with a wrap-around door reinforcer (if wood is worn), hinge reinforcement, and a heavy-duty strike. A holistic door hardening boosts all forms of resistance—covert and forceful.

Where Smart Locks Fit into Pick Resistance

Smart locks add convenience (codes, schedules, logs) but the mechanical core still matters. Evaluate the cylinder, not just the app.

Mechanical Core

Prefer smart deadbolts that accept high-security or restricted cylinders. A great app can’t fix a low-grade plug.

Local Fail-Safe

Ensure keypad access works offline. If batteries die, the keyed override should be a quality cylinder—not an afterthought.

Key Control Still Applies

Even with codes, control physical keys. Use restricted blanks for the override key and store spares off-site.

Two Quick Checklists: Evaluate & Upgrade

Save these to your phone for a fast on-site assessment and a shopping plan that avoids marketing fluff.

- Evaluate Look for UL 437 or high BHMA/ANSI grade • Feel for tight tolerances • Paracentric/narrow keyway • Ask about restricted keys • Confirm installer can provide documentation • Verify door/strike reinforcement.

- Upgrade Choose a Grade 1 deadbolt body • Add a restricted or high-security cylinder (sidebar/sliders) • Reinforce strike with 3-inch screws • Consider laminated/impact glass for nearby sidelights • Keep keys on a documented issuance list.

Answers to Common Pick-Resistance Questions

Quick clarity to help you choose wisely without going down a rabbit hole.

Does “Grade 1” automatically mean pick-resistant?

Are dimple keys more secure than traditional keys?

Do security pins really matter?

Is a locksmith’s “rekey” enough to boost pick resistance?

Should I add a second deadbolt?

How a Locksmith Confirms Pick Resistance in the Field

A qualified locksmith doesn’t just install; they validate. Expect careful door/strike alignment, cylinder fit checks, documentation of grades, and—when appropriate—demonstrations of non-destructive resistance using manufacturer-approved test procedures (never on your active cylinder without consent).

Spec Matching

They’ll match cylinder platforms across doors for key control while balancing cost and risk.

Door Hardening

Reinforced strikes, longer screws, hinge tweaks, and wrap plates where wood is worn—all of which amplify cylinder performance.

Key Issuance Policy

Documented keys with authorization cards prevent unauthorized copies, closing the easiest bypass of all.

Aftercare

Maintenance schedules (lubrication with dry film, periodic alignment checks) keep tolerances tight over time.

Ready to Upgrade to True Pick-Resistance?

We’ll assess your doors, specify a compatible high-security or restricted cylinder, reinforce your strikes and hinges, and set up a sane key control policy—so the easiest way in isn’t your lock. Get a clear, itemized plan that balances budget, convenience, and real-world security.